This is the only heavy metal remediation product that utilizes patented and proprietary technology, allowing it to work in situ and in a way no competitive product can.

Metal Ion Reaction

This product remediates heavy metals by chemically binding to them and rendering them non-mobile, harmless and non-bioavailable in soil, water and other heavy metal contaminated media. This chemical binding process cannot be broken by normal environmental exposures.

Environmentally Friendly Remediation

Heavy Metal Remediation is a one-of-a-kind, patented solution designed to help you effectively prevent and remediate heavy metal leaching and pollution in the most environmentally friendly way. It’s cost-effective, and it works without exposing people, animals or the environment to toxins, harsh chemicals, allergens or volatile organic compounds (VOCs). It is designed to work in-situ, distinguishing it from other possible remediation options.

It works without the use of acids or other harmful chemicals. It is safer and better for people, animals and the environment.

- Is Rapidly Biodegradable

- Is Allergen Free

- Contains Zero VOCs

- Can be Used Alone or in Concert with Other Processes and Products

Heavy Metal Remediation has been proven effective in lab tests and real-world clean-up sites for remediating heavy metals without causing greater risk to the environment.

Use to remediate

- Calcium

- Zinc

- Lead

- Cadmium

- Magnesium

- Chromium

- Iron

- Copper

- Mercury

- Manganese

- Multi-Valent Metals

Works on

- Industrial Plants

- Hazardous Waste Sites

- Brownfields

- Leachate Remediation Sites

- Fly/Coal Ash Sites

- Hog Farms

- Chicken Farms

- Other Animal Waste Operations

- And More

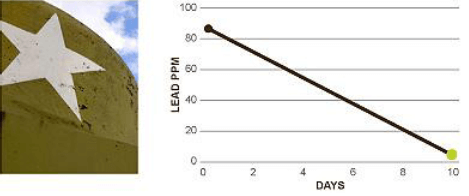

Army Depot

Our technology was used to remediate lead at an Army Depot. Results shown are before treatment of contaminated soil and 10 days after treatment of contaminated soil. Tests results are from an independent third party laboratory using EPA method testing (EPA 7420). Not shown in the chart: a 36.36% reduction in Chromium and 92.22% reduction in Cadmium.

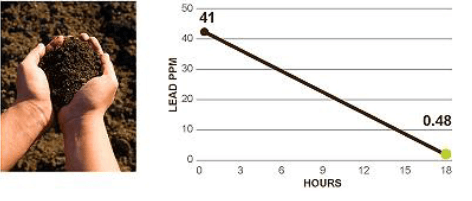

North Carolina

Our technology was used to treat lead-contaminated soil in North Carolina. At the request of a contractor, personnel from an independent laboratory were sent to conduct on-site testing before and after treatment. After an extended 18 hour EPA leachate test, the final result was a 98.8% reduction in lead to 0.48 ppm from an initial 41 ppm.

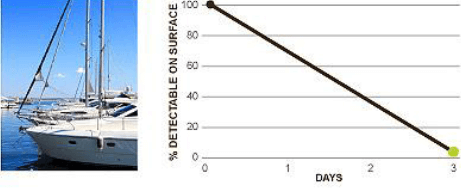

Marina Del Ray

Apartments in Marina Del Rey that were contaminated with lead paint were tested and treated with our technology. The results in the chart are the before and after test results verified by an independent third party laboratory using EPA test methods.

Fly Ash Analysis

At a drilling yard, our technology was used to reduce TPH in soil. A Phase II report on the property revealed an average of 6000 ppm TPH in 490 yard3 of soil. After our product was applied, a reduction to 138-120 ppm TPH was shown in just five days. Further reduction (with no further treatment) showed results down to 23-10 ppm after 27 days.

Highly Effective

Heavy Metal Remediation is effective on both land and water, producing fast results. In field remediations, it has reduced leachable heavy metal concentrations to below regulatory limits quickly and in situ.

Reduces Risk

Using this product can reduce health/environmental risks and legal liability.

Safer & More Effective Than Storage Tanks & Landfill Liners

Many hazardous waste storage methods – underground storage tanks and landfill liner systems – leak chemicals, contaminating the groundwater. Heavy Metal Remediation actually remediates contaminated soil, sludge and water.

Cost Effective (In Situ or At Landfills)

Using Heavy Metal Remediation is cost-effective, whether you use it in situ or at a landfill.

In Situ:

A key benefit of Heavy Metal Remediation is that it allows you to conduct treatments in situ – at the site of contamination. When you remediate toxic waste in situ, you don’t have to pay to transport it to and dispose of it in a hazardous waste landfill. Also, there is no need to bring in fill dirt to replace what was removed.

At Landfills:

Using Heavy Metal Remediation offers significant cost advantages over encapsulating heavy metal at landfills. It remediates heavy metals, allowing you to save time and valuable landfill space.

Heavy Metals Contamination

This Technology can remediate heavy metal contaminated soil, water and other media (including coal ash).

This product has been used to remediate lead, copper, zinc, arsenic, chromium, mercury (in fact, all of the RCRA 8 metals and more), in many cases to non-detect levels. This technology can also be used for more complicated wastewater challenges with multiple contaminants.

Many commercial operations produce liquid waste that is too acidic to be directly released and must be pre-treated before it will be accepted by a publicly owned treatment works. Heavy Metal Remediation starts the remediation of fats, oils and grease, reduces odor and buffers the pH to meet direct discharge standards and has been proven to reduce ammonia nitrogen in wastewater below regulatory levels quickly and easily.